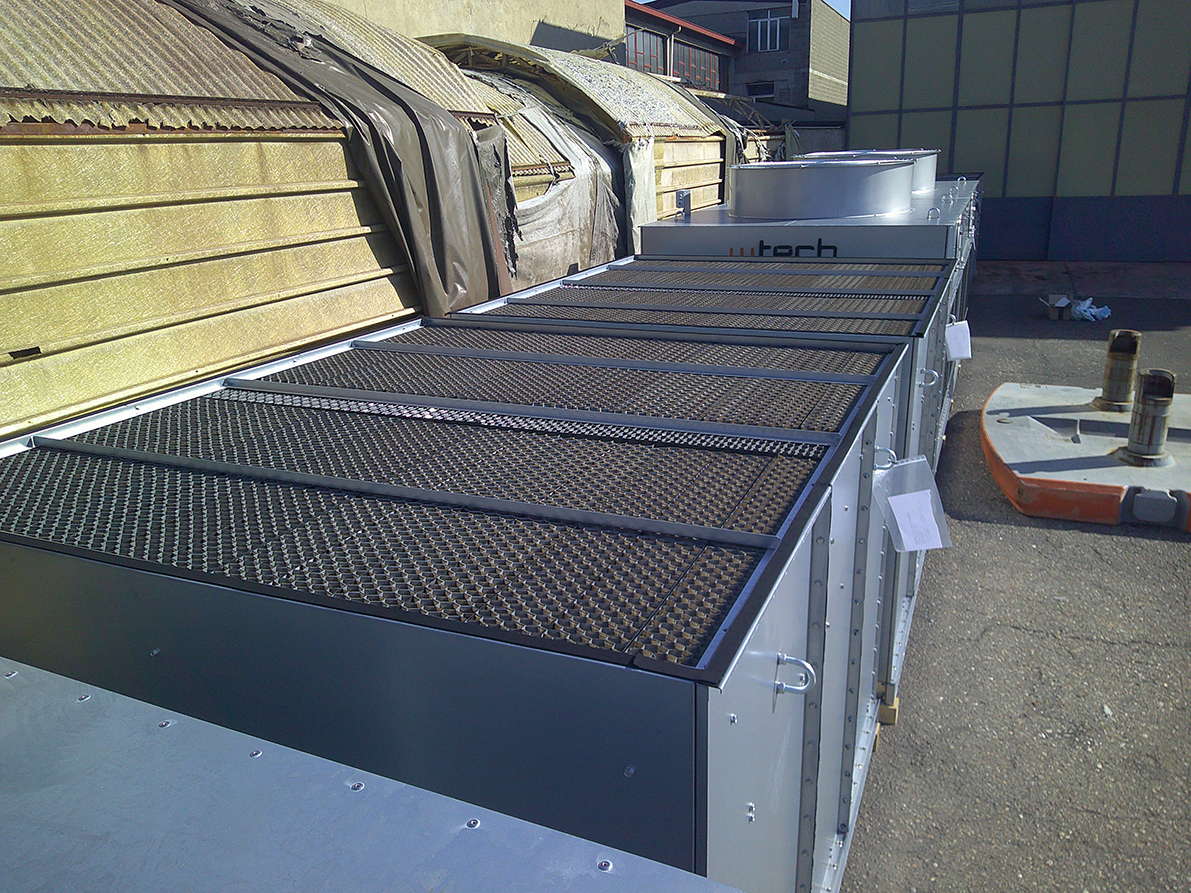

For a main chemical group, Tempco has recently completed the supply of an adiabatic free cooling system that serves the production lines of basic products for the cosmetics industry.

The customer’s facility employs a system served by chillers, and as part of a new investment has considered to enhance the system with the integration of an adiabatic free cooling system, in order to save energy and optimize the production process. Tempco therefore provided the initial study to evaluate the effective potential impact and advantages that free cooling could guarantee to the customer, in terms of greater efficiency and energy saving.

Once the investment was approved, complete with the calculation of the related ROI, we supplied a dry cooler combined with the control and pumping system of the plant, in order to integrate everything with the existing refrigeration system. The solution obviously uses inverter-controlled fans, which guarantees regulation of the speed and the reduction of related energy consumption based on actual process needs.

Lastly, we have supplied a series of shell and tube exchangers for the temperature regulation of the diathermic oil, which is also achieved thanks to the free cooling system.