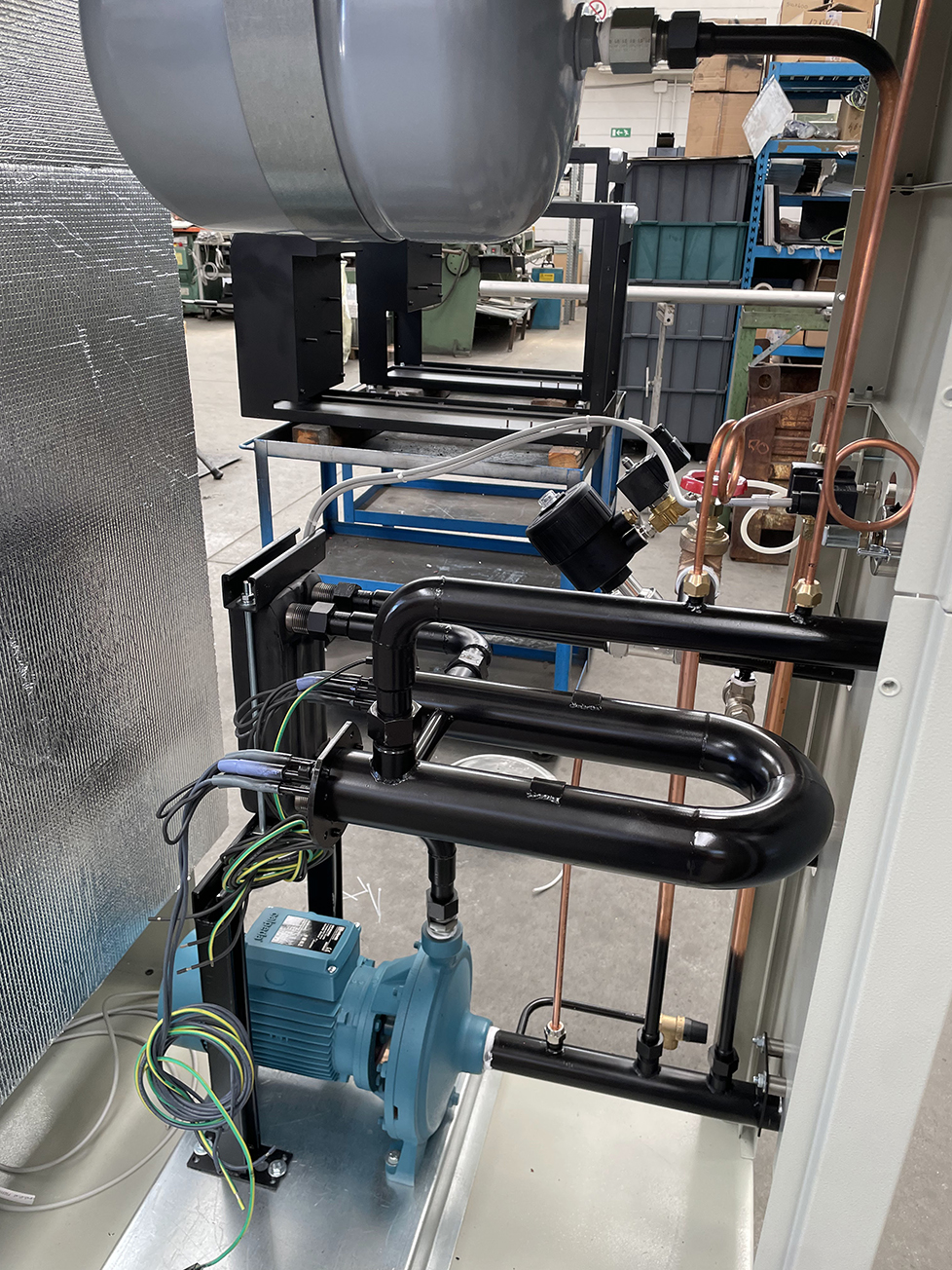

The exponential global growth in computational capacity is driving the energy consumption of high-power chips. In AI and HPC (High Performance Computing) data centers, increasing power density is pushing air-cooled systems to their physical limits. On the other side, liquid cooling technology, which until recently was marginal, is rapidly becoming a core infrastructure, offering the significant advantage of ensuring thermal efficiency hundreds of times greater than traditional air cooling.

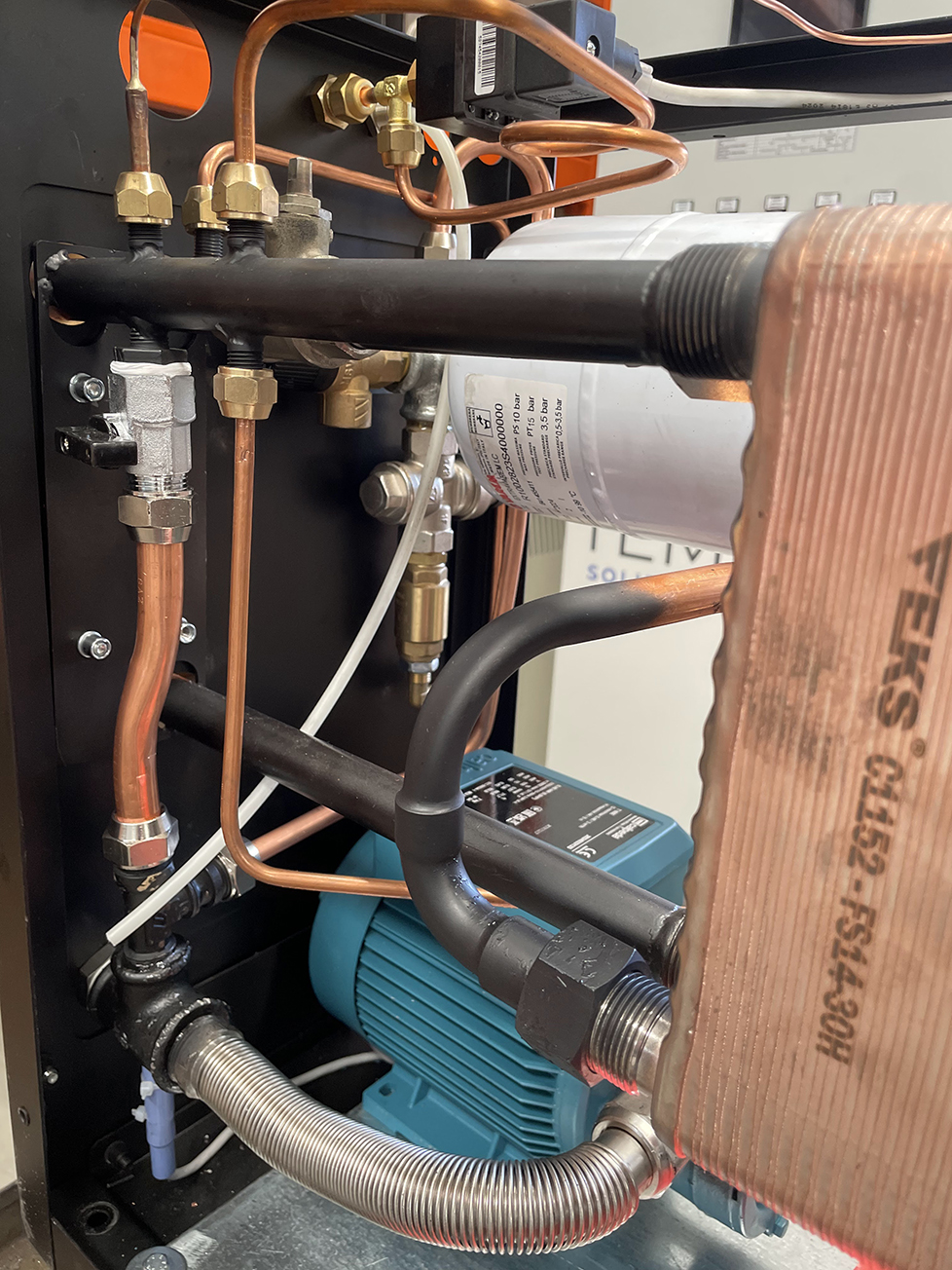

The AI/HPC data centers sector is therefore accelerating its transition toward the use of large-scale liquid cooling technologies, driven by the achievement of sustainability targets and high power efficiency (PUE) values in new, large, high-performance data centers. To address this significant trend, Kaori, a Tempco partner in the field of heat transfer, recently introduced two new heat exchangers with highly attractive features specifically designed for new liquid cooling solutions in high-performance infrastructures.

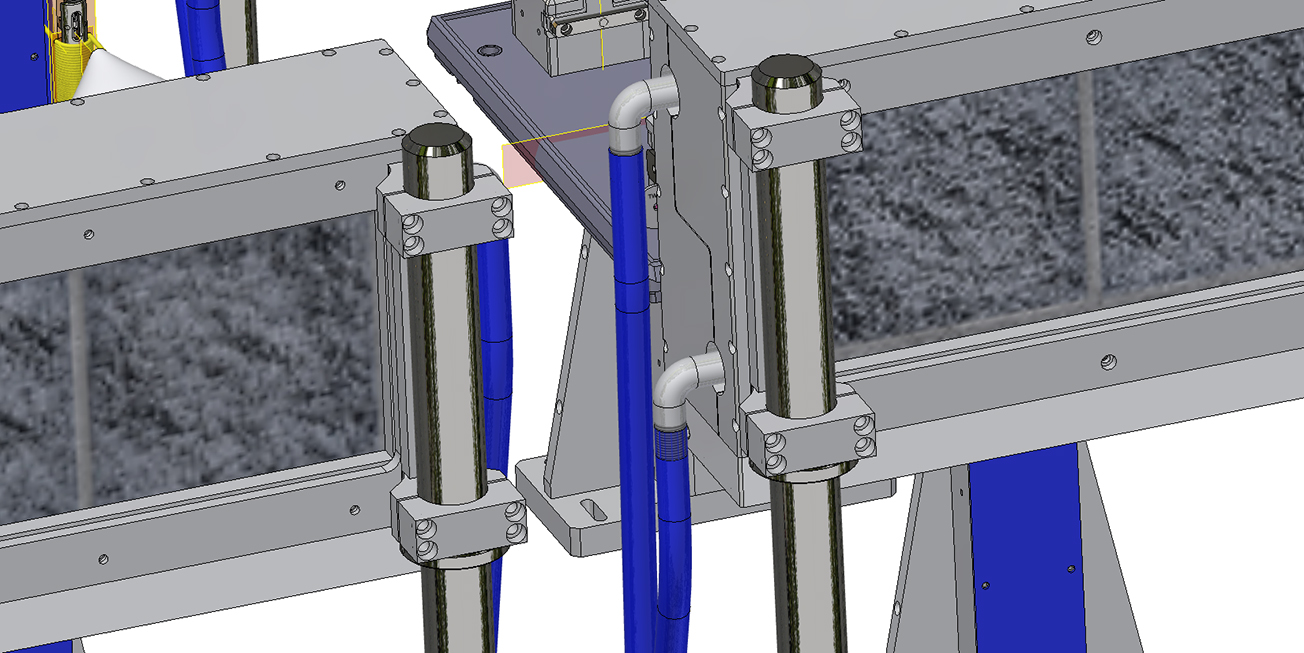

This is the B390 heat exchanger, which features an asymmetric plate design specifically designed for high-density AI and HPC data centers. With a cooling capacity of up to 2.000 kW and support for 4-inch high-flow connections, it easily manages the transient heat loads of next-generation high-power servers. Measuring only 321 mm in width and 751 mm in length, the B390 offers exceptional cooling performance in a compact footprint—perfectly integrating into In-Row CDU systems while maximizing space efficiency.

Optimized for the pressure drop differences on both sides of In-Row CDU systems, the B390 ensures stable flow distribution and higher overall performance. It is available in single or multi-pass configurations and supports vertical, horizontal, or flat installations, providing flexible integration for various system and space requirements in data center environments.

B390 continues the core advantages of Kaori’s B Series:

- Exclusive plate pattern design: maximizes heat transfer efficiency while maintaining low pressure drop.

- High working pressure construction: ensures long-term reliability for high-pressure liquid cooling systems.

- Compact design: pptimizes space utilization to meet high-density integration needs.

A second interesting heat exchanger model, also developed specifically for next-generation, high-density data center environments in the AI era, is the K390. The same-sized K390 heat exchanger features a symmetrical plate design, ideal for balanced bidirectional flow systems.

Together, the B390 and K390 form a complementary solution, offering greater design flexibility and performance options for in-row liquid cooling architectures.